Wire Bending Machine

What is wire bending?

CNC (Computer Numerical Control) wire bending is the process by which we use Wire bending machines to bend and cut different types of wire to be used for a wide variety of functionalities.

What is a wire bending machine?

This is type of bending machine which is rapid prototype machine that can bend metal wire to produce a variety of 2D or 3D shapes. It is also quite capable in creating perfectly bent shapes in very short amount of time for both long and lengthy requirement or even for shorter parts with ease.

The application of wire bending machine can be found anywhere from zigzags, squares to hooks, circles and variety of shapes across different industries.

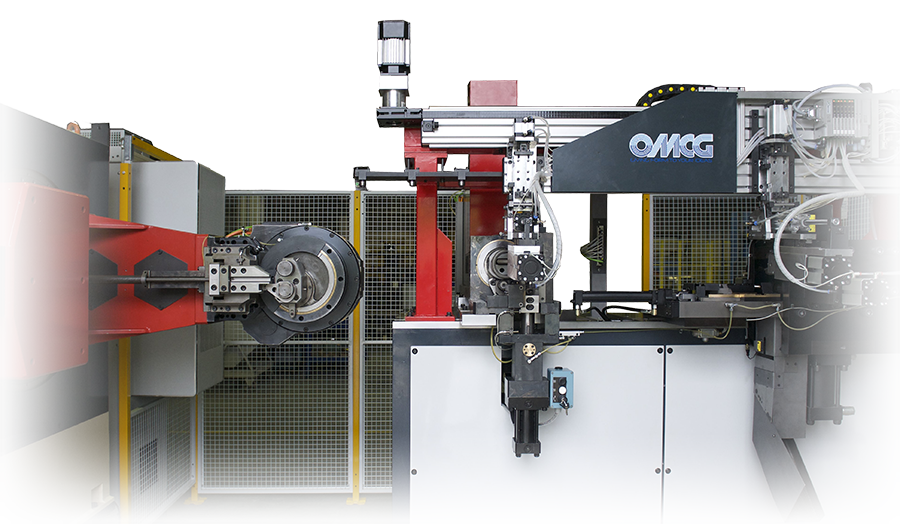

OMCG Italia

Established in 1963 from the diligence and avant-garde insight of Mr. Luigi Maggi, who introduced a completely innovative multi-slide machine’s concept and the first 6 axes CNC wire bending and forming machine on the market, OMCG "Officine Meccaniche Costruzioni Generali" has grown to become a core brand in the manufacturing of machines for this industry.

Operating in over 45 countries, OMCG is one of the few worldwide companies able to supply a whole range of solutions for the bending and forming of wire, tube, and strip by means of CNC benders and special machines designed to meet specific needs and respond to a constantly evolving market.

Our different wire bending machinery products are:

Minimalist 6 -The fastest model thanks to the front feeder placed on the arm.

For smaller wire diameters: from 2 to 6.35 mm.

C61B -Our worldwide most popular and appreciated model.

For wire diameters from 2 to 8 mm.

C31E-The most flexible model thanks to the innovative eccentric head.

Available in three versions for wire diameter from 3 to 18 mm and in three versions for tube up to 16x3 mm.

C20W.10 2.0 - It is the new version of the legendary model, available for wire diameters 3-10 mm and strip cross-sections up to 12x4 mm.

What are the Features of the Wire Bending Machine?

- Standard CNC machinery for bending and forming wire from 2 to 18 mm diameter, tube up to 16x3 mm and strip up to 12x4 mm, equipped with our intuitive and easy-to-use “Easy Programming 4” Software.

- Special machines are designed to meet specific needs and respond to a constantly evolving market.

- Accessory units to be integrated inline to provide secondary operations (end-forming, chamfering, punching, notching, marking, welding, 3D measurement, etc.) or used as standalone units.

- Mechanical parts (straighteners, 3-position flippers, motorized infeed units) for a safe set-up, higher machine performance, parts accuracy, and overall efficiency of operations.

The compliance of our machinery with the requirements of Industry 4.0 translates into production standards of high precision, reliability, programmability, and repeatability. OMCG’s 4.0 solutions make it possible to program, simulate and produce parts in a simple and rapid way, increase productivity, control the quality, reduce waste, remotely monitor plants, schedule maintenance.

Our bending machines produce parts for the main industrial sectors. Our highly reliable machines along with our skilled team members can ensure wire forms are cut with absolute precision.

Thanks to the high manufacturing quality of parts, we can respond to the different demands and meet the specific needs of the manufacturers.

Benefits of Wire bending machines

- It has a high precision

- There is a high level of automation and hence it does not require very high skills to operate.

- It has the capability of providing a perfect cut or bend.

- They save money through efficiency increase, by recreating the programmed design on a continuous basis.

Hytek Marketing has always been able to acquire products of the highest quality and demand to meet the requirements of our clientele. Our partnership with Wire Bending Machine giants such as OMCG could be of great benefit to our clients. If you would like to enquire about the range of products from OMCG, contact us at hytek@hytekmarketing.biz or give us a call at +912040036057/229/48600290, we’ll be more than happy to assist you.