Corner Forming Machines

The new and improved Corner forming machines based on the latest technologies had made corner welding of the past obsolete. The arrival of the corner former, it has opened up new opportunities into the world of metal sheet production. Which includes the production of doors, panels, and road signs.

This sheet metal corner forming machine can be used to bend a wide variety of materials including mild steel, stainless steel, aluminum, etc. with no size limitations.

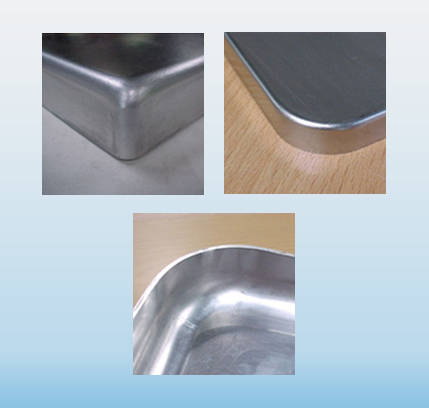

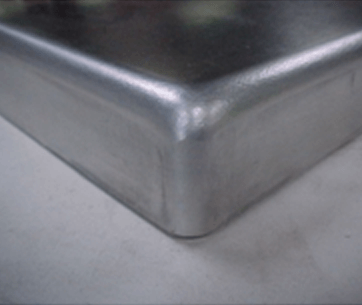

Our sheet metal former corner machine is used throughout the world in the fabrication of different parts, like panels, doors, or road signs. The new tooling design allows former corners in any flange height in connection with any material thickness up to 5 mm. The former corner radius can be determined from 2 mm up to 100 mm. Certain former corner angles from 60° up to 150° are formable on our specific tools.

Corner former Machine without size limitation

ACF Corner former, with its unique working process of being a flexible corner forming machine. It has no size restriction in the production process of sheet metal parts. Classic presses have a clear disadvantage as the size of the parts that can be bent is determined by the size of press tools that are not flexible.

The new tool design of our corner former enables corners with any desired flange height from 0.5mm to 5mm material thickness - depending on the material! The corner shape radius ranges from 2 mm to 100 mm and will be determined individually. Special corner angles from 60 ° to 150 can be easily shaped with our tools.

What are the Advantages of the corner forming tool?

- No welding

- No grinding

- Flexible

- Improve production process

- No size limitation of parts with corner former machine

- Fabrication of different parts can be possible as panels, doors, or road signs

Which are the common shapes made from corner notching equipment?

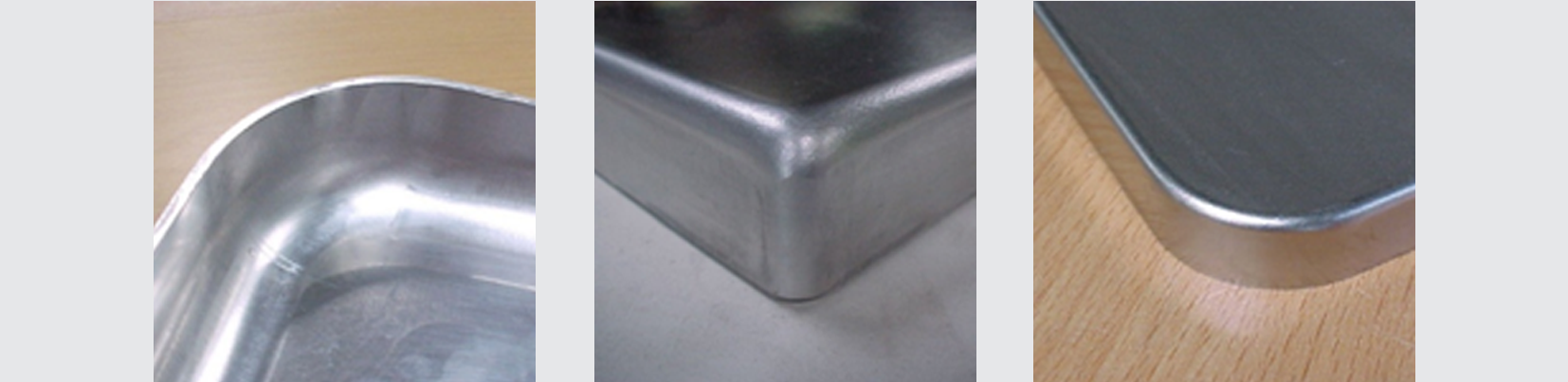

ACF corner forming tools can be used to form all the major shapes in different sizes that can be seen in our day-to-day life. Some of the examples are as follows.

- square

- rectangle

- triangle

- octagon

- Arrow shapes

Due to the multitude of possible applications in the production of cold-formed corners, this corner-form all-rounder is used worldwide in the production of various sheet metal parts.

Where do we implement ACF corner forming machines?

- Drip trays for air conditions

- Fire oven doors

- Road signs in any shape(including octagonal shape and triangle shape-even as beading machine)

- Communication equipment covers

- Compressors cover

- Trays

- Cooking trays

- Bottom for vessels

- Ceilings

- Container covers

- Doors for electrical cabinets

Why do we use a welded corner forming machine?

ACF corner forming machines can make your work easily, quickly, and inexpensively with its array of flexible machines, primarily ACF flexible corner forming machines.

Old-formed corners of the previous generation can form sheet metal in perfect quality but ACF are much better and easier to use than welding corners by utilizing its revolutionary flexible corner former.

So why do you have to keep relying on welding and grinding corners?

For sheets of any kind, the ACF corner former that is supplied by Hytek Marketing across India has the capability to make your tasks easier and will always deliver a consistently perfect corner quality at the lowest possible cost. Along with our line of aluminum corner all-rounders which could be considered as the ideal tool for the production of Traffic signs. The different sizes of the traffic signs do not influence the tool costs. The shaping of the corners, including the trimming process, can be carried out quickly and easily on the ACF corner former. That saves time and money! The ACF corner former provides a perfect solution wherever corner welding is too time-consuming. A flanging machine is to a certain extent combined with the corner press. This flexible machine is comparatively cheap compared to the acquisition costs of the individual devices.

The service life of the flexible tools in our corner former is very long. Not least because of this, our way of corner production is much more efficient than with the classic welding method

Hytek marketing has always been able to acquire products of the highest quality and demand to meet the requirements of our clientele. Our partnership with corner forming machines giants such as AFC could be of great benefit to our clients. If you would like to enquire about the range of products from Hytek Marketing, contact us at hytek@hytekmarketing.biz or give us a call at +912040036057/229/48600290, we’ll be more than happy to assist you.