Plasma Cutting Machines

What is Plasma cutting machines?

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.

What is the purpose of CNC plasma cutting equipment?

Plasma cutting is a melting process in which a jet of ionized gas at temperatures above 20,000°C is used to melt and expel material from the cut.

Advantages of Plasma cutting system

- Able to cut all conductive materials. Flame cutting, though also suitable for cutting thick metals, is limited to ferrous metals only.

- Great quality for thickness up to 50 mm.

- Maximum thickness up to 150 mm.

- Comparatively cheap for medium thickness cuts.

- Best way to cut medium thickness stainless steel and aluminum.

- CNC machines are available to provide high precision and repeatability.

- Can cut in water, resulting in smaller HAZ. Also reduces noise levels.

- Smaller cutting kerf compared to flame cutting.

- Quicker cutting speed than oxyfuel.

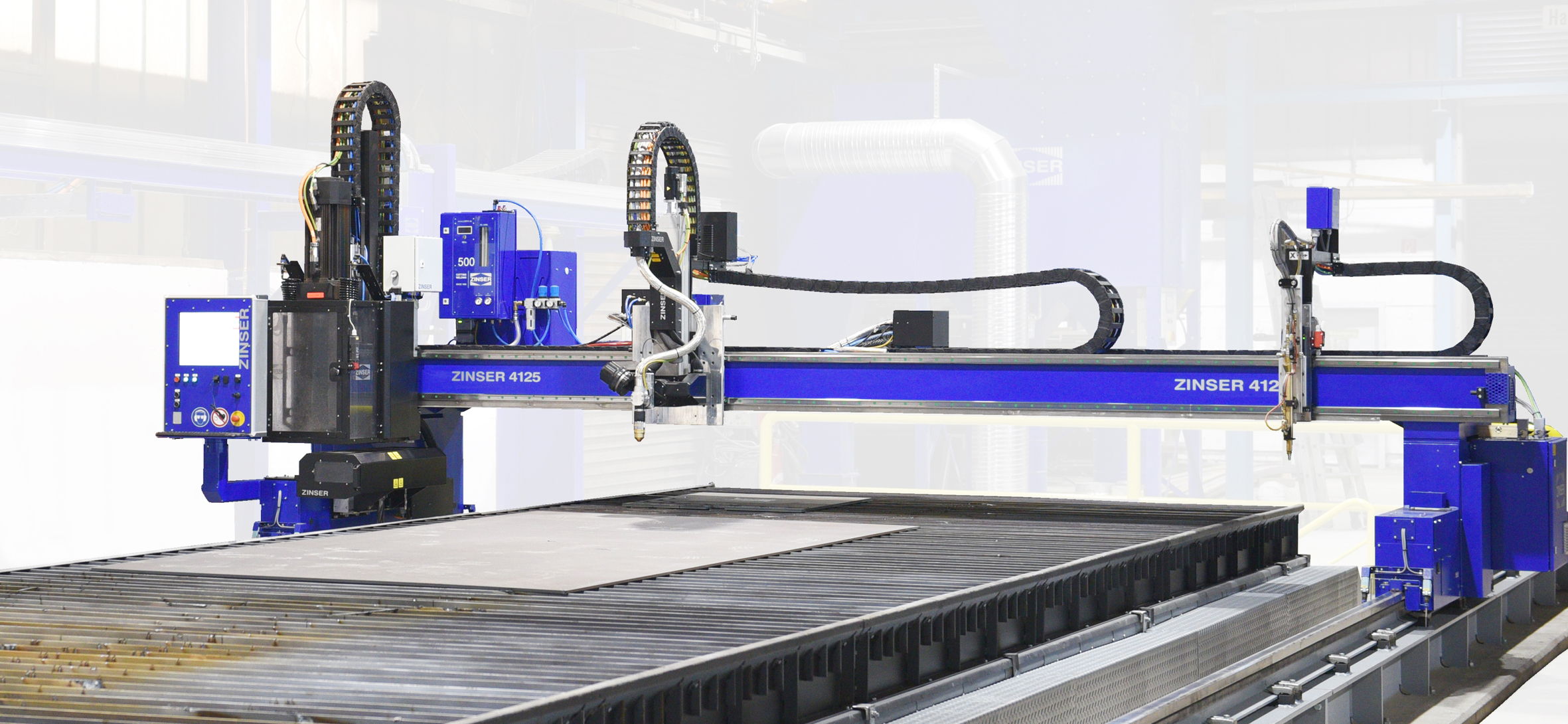

Zinser is your strong partner in the areas of flame cutting systems, oxyfuel technology, and hot air devices. Quality and the satisfaction of our customers are our first priorities. Name your task and we will find a solution together! Hytek supplies the best plasma cutting machines for the smooth running of the business.

Zinser manufactures different types of cutting tools:

- CNC cutting machines

- Plasma cutting machines

- Oxy-fuel cutting machines

- Portable flame cutting machines

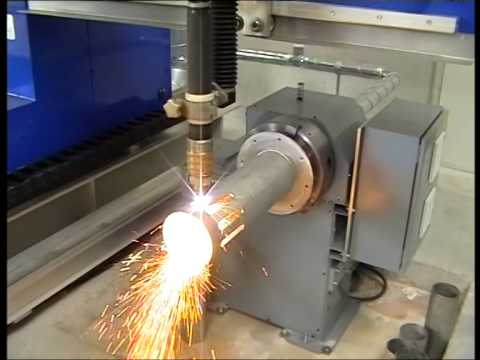

- Pipe cutting devices

- Plasma consumables

- Software

- Oxy-fuel technology

- Used machines

- Hot air devices

The Zinser CNC cutting systems are renowned around the world for their high quality and customized products “made in Germany”.Hytek combines tradition with innovation and realizes the needs of its customers. Our reputation as a worldwide known company is based on our expertise in the field of flame cutting and plasma cutting systems.

Features of Zinser plasma cutting tool

- Hytek offers more than just standard flame cutting machines.

- With us, you always get the leading technology.

- Also, we provide you with the necessary tools to achieve the optimal results possible.

- CNC cutting systems for demanding production processes

Premium cutting systems 4000 series

The machines of the Hytek premium series are known worldwide for their excellent cutting quality.

Whenever extraordinary machine reliability is required, like in the steel industry, customers have relied on Hytek machines for decades.

Hytek 4025B / 4125B / 4026B / 4126B

These Hytek premium machines offer the perfect solution for every cutting task – whether oxy-fuel, plasma, laser, or bevel cutting – drilling, thread cutting, pipe, or heavy-duty cutting.

Hytek Marketing has one of the most finely tuned, broadly used, efficient, and adaptable Plasma cutting tools for cutting even heavy and thick materials quite easily. We provide CNC plasma cutting machines that can be utilized for a variety of materials and projects, ensuring the safety of the workers by helping you to safely cut metals that are not possible with other cutting solutions.

It is applied for various metal fabrication jobs in construction and decorative purposes and used by artists and designers to bring their visions to life. Attain a smooth and professional finish for your sculptures and signs through plasma cutting machines. A very versatile Plasma cutting machine for almost For any of your projects that involve metal or steel, which is why it’s been so popular for many years.

Why Plasma Cutting Machines?

1. Versatile

You can use our Plasma cutting machine on diverse types of metals like steel, iron, copper, brass, aluminum, stainless steel, and other durable materials. Cut the most difficult material parts stacked on top of one another that too in the fastest cutting speed. Compared to Oxyfuel cutting machines, plasma cutting machines are more versatile. They also can produce the most versatile cutting and your end result will be how you have already visioned.

2. Easy to use

Plasma cutting machines that are portable and easily movable to any place wherever the job demands at your convenience. Hytek Marketing supplies plasma cutters that can be easily handled by a single operator who is well knowledged and trained. They are really safe and reliable solutions for cutting metal.

3. Quick Cuts

Plasma cutting machines give you the relatively fastest cutting solution. Compared to the speed of other cutting tools plasma cutters will give you the quickest cut since it’s a time saver and a lot easier than other cutting equipment. Compared to other cutting tools, a quarter of the time is needed for a plasma cutter to get the jobs done. They save cutting time and help you to complete your project in no time since plasma cutting tools don’t need to be preheated before cutting.

4. Precision

We supply plasma cutting machines that give the best Precision or accurate cutting. Now it’s really easy to cut different shapes or angles with sheet metal with the greatest precision which you have visioned for. This is the main reason why you should choose Hytek before choosing a plasma cutter if you want to complete your project with accuracy and on time.

5. Cost-effective

Hytek’s plasma cutting machines will give you the best and fastest precision cutting with less wattage and little loss due to on-the-job injuries. This will help you to reduce the cost of production.

6. Fastest Piercing

Hytek Marketing provides plasma cutting machines d accurate cutwith incomparable piercing speed. Now any difficult piercing is easy with our plasma cutters, especially when there is a cutting application that requires inside piercing. And since they do not have to be preheated they can do the same piercing of 15 mm metal in 2 seconds, that an oxyfuel does in more than 30 seconds. So it will take less time to pierce and less money charged to the end user.

7. Safety

The plasma cutting machines that we distribute are designed and manufactured to make sure that the safety requirements are met. Since plasma cutters use gas that is not highly flammable for the cutting purpose it’s considered a safer method than other processes. And we have also a collection of plasma cutting machines that are carefully designed to make ensure the safety of the workers. But before working on metal it is good to make sure with experts to ensure a safe and accurate cut.

8. Applicable for a variety of thickness

Our team offers plasma cutting machines that can cut metals of up to 150 mm in thickness. So that you don't have to miss any opportunity that is coming to you, you can work on a variety of projects. Compared to any other metal cutting options, we can cut a much thicker piece of metal.

9. Variety of Shapes

You can create almost any shape or line imaginable with our plasma cutting machines whether it’s straight lines, curves, or intricate shapes which are difficult to build with other cutting tools. No matter how challenging your project is, the precise beam on the plasma cutting machines will ensure high accuracy.

10. Energy-Efficient

Hytek’s plasma cutting machine will ensure an energy-efficient process. Compared to any other cutting options plasma cutters are a more sustainable solution, this is why most of the construction industry depends on Hytek Marketing for their cutting solutions.

Hytek Marketing has always been able to acquire products of the highest quality and demand to meet the requirements of our clientele. Our partnership with Plasma Cutting Machines giants such as Zinser could be of great benefit to our clients. If you would like to enquire about the range of products from Zinser, contact us at hytek@hytekmarketing.biz or give us a call at +912040036057/229/48600290, we’ll be more than happy to assist you.

.jpg)

.jpg)